The RUD PIP-RAPIDO.

Turn. Insert. Click. Done.

The first ever plug-in lifting point. From RUD.

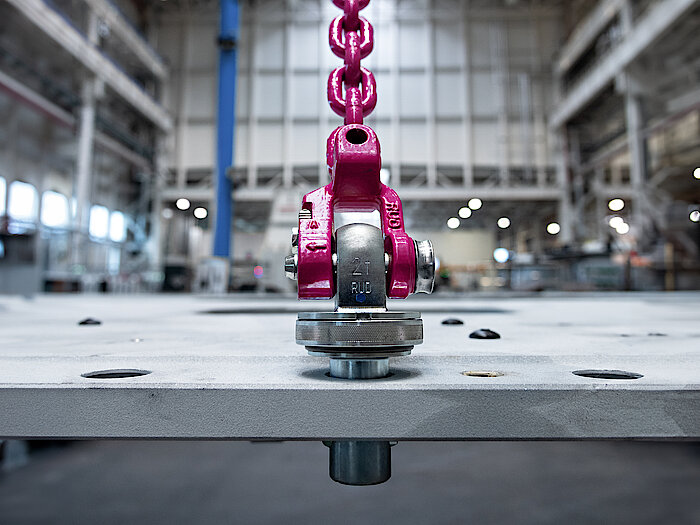

During lifting operations with loads that vary on a regular basis, the assembly and disassembly of boltable lifting points cost valuable time. The solution: the new RUD PIP-RAPIDO, which sets new standards in efficiency and handling with its innovative plug-in mechanism. All without the need for tools.

All advantages at a glance:

- Quick, tool-free mounting.

- Up to 80% time savings compared to boltable lifting points.

- Ideal for through-holes (e. g. flanges) with hard-to-reach rear sides – and with undercut holes.

- Greater flexibility with tolerance ranges of 2 mm (diameter) and 10 mm (length) without compromising load-bearing capacity.

- Available in diameters ranging from 30 to 41 mm and lengths from 16 mm to 100 mm.

Doesn’t waste any time.

Turn. Insert. Click. Done. The RUD PIP-RAPIDO can be mounted by hand in just a few steps. This results in a huge time advantage and significantly increased efficiency. Additionally, the tool-free mounting and dismounting make for a noticeable handling advantage.

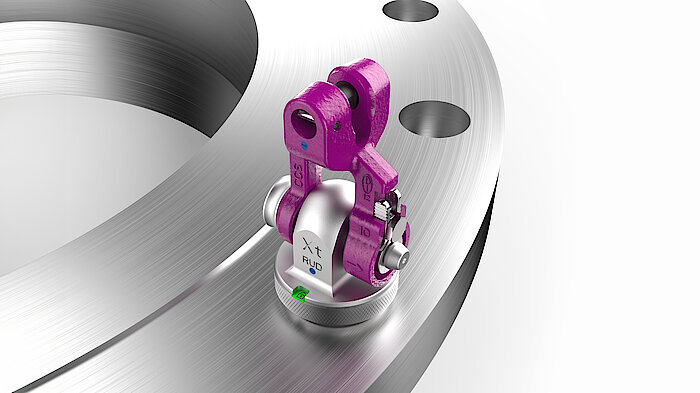

Easy and safe to mount.

The RUD PIP-RAPIDO’s locking mechanism can be released by simply turning it. When the support elements are retracted, the red symbol is visible, and the lifting point can be mounted or dismounted. When the green symbol is visible, the support elements are extended and everything is ready for lifting—thanks to the integrated spring mechanism, this step takes place automatically.

No Access? No Problem.

Its innovative plug-in mechanism makes the RUD PIP-RAPIDO the perfect lifting point wherever space constraints make it difficult or impossible to reach a nut during assembly or disassembly. It is also the ideal solution for holes with undercuts. Thanks to its functionality and exceptional flexibility, the RUD PIP-RAPIDO provides significant added value, even when accessibility is good.

Here’s how it works:

the PIP-RAPIDO in action.

Less effort, greater efficiency – when does the PIP-RAPIDO pay off for your company?

The PIP-RAPIDO saves you valuable time during installation. Our calculator shows you how quickly the additional cost of the PIP-RAPIDO is offset by the time saved. Simply enter your individual parameters to find out when the PIP-RAPIDO becomes a worthwhile investment for you.

The result shows after how many working days the additional cost of the list price of the PIP-RAPIDO plug-in lifting point is amortised through the assembly time saved, compared to the list price of a conventional lifting point (here compared to the VLBG-PLUS).

The calculation considers how many lifting points you use per lifting operation, how much time you save per operation with the PIP-RAPIDO, the internal hourly cost in your company, and how often lifting operations are carried out each day.

The higher your time costs or the number of lifting operations, the faster the PIP-RAPIDO pays for itself.

If you have any further questions or would like personalised advice, our team of specialist advisors will be happy to assist you. Please use the contact form to get in touch with us.

The right sizes for a variety of applications.

The RUD PIP-RAPIDO is currently available in bore diameter from 30 to 41 mm and lengths from 16 mm to 100 mm. Another unique feature: Tolerance ranges of 2 mm (diameter) and 10 mm (length) ensure greater flexibility without compromising the load-bearing capacity.

The key technical data:

- WLL: 0° - 45° → 4,2 t.

- Bore diameter: 30 - 41 mm.

- Lengths: 16 - 100 mm.

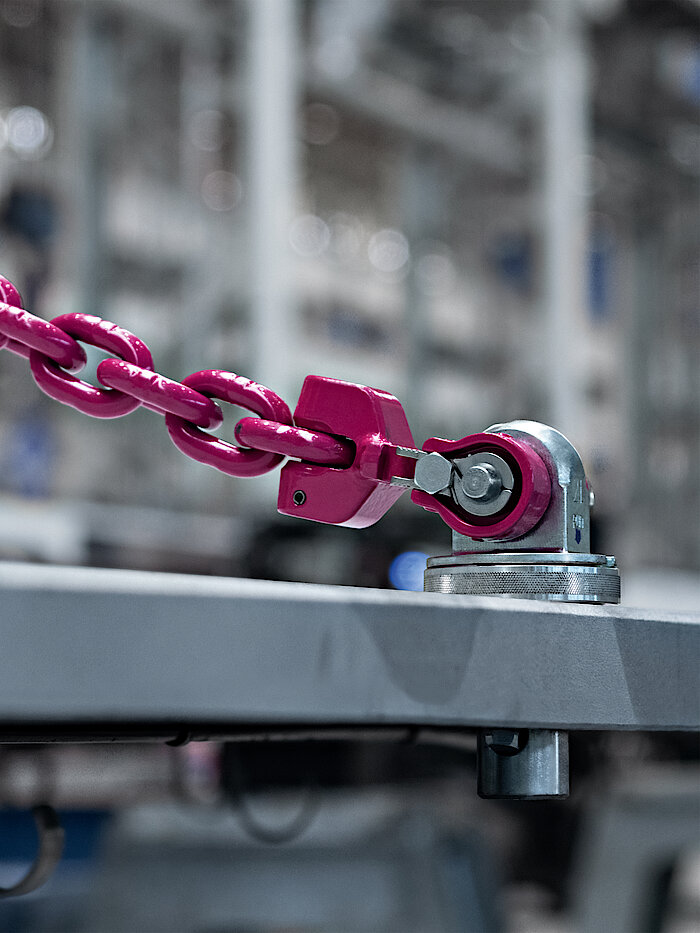

Perfectly combined – for maximum time savings and handling benefits.

Two innovations – one complementary benefit: Our first clickable clevis shackle – CCS-FASTLOX – is the perfect complement to the PIP-RAPIDO plug-in lifting point. Insert, click, secure, done.

Save time and money: wireless inspection documentation via RFID.

In more and more countries, regular inspections of lifting means and their documentation are mandatory. The RUD ACP-TURNADO’s standard integrated RFID tag allows its factory-issued ID number to be called up at lightning speed using a reader or smartphone. This makes it easy to assign the test results – saving you time and money.

Request information now.

Please use the contact form for further questions about our products and service features.

Our Team will be pleased to help you. Just call us or send us an e-mail.